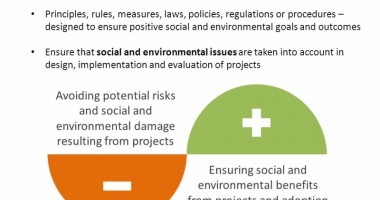

Using in-house strategy, Environmental Safeguards Strategy has been prepared for the Malaba-Kampala section detailing procedures to ensure that all the environment laws and regulations are observed.

Progress

The Government of Uganda continues to make significant progress in the development of Standard Gauge Railway in the country.

Environmental Safeguards Strategy

Social Safeguards strategy

Again using in-house approach, a Social Safeguard Strategy has been prepared and approved to ensure that the social, cultural, HIV/AIDS prevention and other norms are observed. It draws experience from the challenges we have had in the construction sector concerning social and cultural issues.

Capacity Building Strategy

This has been prepared using in-house approach, aimed at transfer of technology skills to the indigenous Ugandans, especially in the areas of design construction and O&M.

Occupational Safety and Health (OSH) Strategy

The OSH Strategy was prepared to ensure that construction regulations and guidelines are strictly followed.

Quality Assurance Strategy

In order to ensure that the works done and services provided meet the standard as stipulated in the contract, a robust Quality Assurance Strategy has been prepared which includes the design review strategy, construction assurance strategy and the materials quality control strategy. A laboratory will be established and equipped to help the employer carry out the quality assurance function. This stringent mechanism is required to ensure that the railway system functions as designed and lasts for a period of 100 years.

Local Content Strategy

Using in-house capacity, the Project has prepared a Local Content Strategy which describes how the Project will ensure that at least 40% of the value of works is spent locally. The local content ratio will be 9:1 Ugandans to foreigners. The Project has discussed with cement manufacturers to produce the low alkaline, low sulphate good grade cement required for railway construction; it has discussed with steel manufacturers to produce the steel required for the railway concrete structures. Further discussions with UNABCEC are under way to ensure sub-contractors do take on some of the civil works. Discussions with PSFU and Ministry of Education are ongoing to ensure that at least a minimum of US$700m is spent locally.

To ensure that all the materials that come into the country meet the quality mark in compliance with the standard, the Ministry / Project have signed an MoU with UNBS. UNBS/Project will not only carry out pre-shipment inspections but also pre-production, in-production and post-production of the equipment, locomotives and rolling stock for SGR. UNBS will also improve their laboratories to test the construction materials that will be used on the Project as per agreed testing regime and standards. The Bureau will also recognize the Chinese Class 1 railway standards used by the Project as the official/legal standards for development of SGR.

CONNECT WITH US

Standard Gauge Railway Uganda

Developing the Tororo-Kampala (Eastern) and Tororo -Amuru-Packwach (Northern) routes